CNC Hydralic Press Brake

esskay machines offers wide range of CNC Hydraullic Power Press Brakes which are easy to maintain, versatile and have low tooling cost. The all steel structure ensures robust press brake body. Our press brakes are designed to operate on low pressure, as compared to many of our competitors who design their press brake to opearte on high pressure which may result in damage of seals, threreby affecting its accuracy and further may result in leakage. Our design facilitates leak proof and accurate operation even under load higher than nominal limit.

40 Ton to 600 Ton.

The standard bending length is 2500 mm and 3050 mm, longer machines (up to 7 m) can be manufactured as per customer requirement.

Numerically controlled back gauge package:

Consists of an internationally reputed make AC Servomotor, Servo drive, PLC controller and 7” COLOR TOUCH SCREEN TFT DISPLAY for desired and current back guage position.

Back guage hardware consists of a reputed make ball screw with nut, LM Guide ways, timing pulley & timing belf for precise movement of the guage.

NC Back guage will have multibend betch processing function up to bends.

Standard Features

• Dead stop arrangement of accurate bending with 0.001mm repeatability which ensures the same bend angle in each stroke.

• Stroke length van be preset

• Numerically controlled back gauge from front side of the machine

• Inching and auto cycle feature

• Cylinders from high quality forged steel are precisely honed. Piston rods are hard chromed for for longer life.

• Rigid structure with interlocking design ensures minimum deflection even under maximum load

• Electric Control Panel with selection of Auto, Inch and Single Cycle Auto Mode oparation

• Mechanical stop and steel torsion baar to maintain synchronization and high precision

• One suitable 5-way die and punch

• Main drive motor

• Pair of foot switch

Optional Features

• Crowing Device

• Numerically Controlled back Gauge Package

• Extra Tooling set as per customer requirement

• Higher throst depth

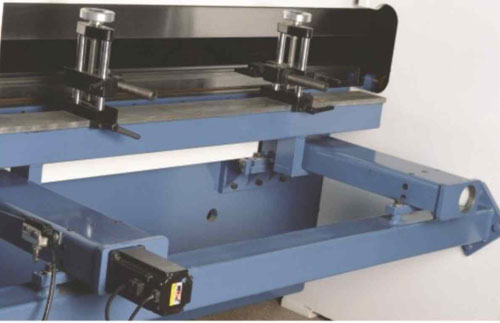

Numerically controlled back guage

The machine has a precision heavy duty back guage with ball screws & liner motion guideways, designed to give long service life and better accuracy. The guage stopper heads are adjustable with quick release manual clamps, with single dovetail location to ensure precise repositioning. The vertical movement (R-axis) and cross (Z-axis) of back guage heads are manually adjustable.

Dead-stop Arrangement

It is unique teature to meke sure that repeat accuracy is achieved in bending, Depth control can be set manually with the help of handle to set the desired angle. It works in conjunction with Dead-stop arrangement and gives repeat acciracy of +-5u.

Operators Console

Ergonomically mounted operator’s console for comfortable operation. The controller is mounted on arm that can be swung towards or away as required.

TFT Touch Screen

7” Full Color TFT Touch Screen Display. Selection of auto/manual mode can be done on-screen. Machine control such as Ram up, Ram doen, B/G forward, B/G reverse can be done on the screen. Batch program can be created/modified easilty by single touch.

Machine Synchronizing Bar

Both the cylinders (Y1 & Y2) are synchronized with the help of torsion bar and links. This arrangement is used to bring the upper beam parallel to the bed all through the stroke.

Electrical Control Panel

Located on the right side, the main panel is assembled from internationally reputed parts for consistent performance and reliability. It is wired cleanly and properly labelled as per international practices to help easily locate any fault and replace components conveniently. Moable foot-switch helps control up-down motion of the ram from any convenient position.

Toolings

One set of die-block with multi ‘V’ grooves and straight upper blade is supplied with the machine. Mutiple clamps provided to assist clamping of segmented top tool. Toolings as per job applications can be suggested and supplied (Optional). Also hardened and ground tooling can be provided upon request.

Hydraulic Cylinders

All our cylinders are manufactured in house using UT seamless tubes. Bore of the cylinder is precisely honed to mirror finish to maintain dimensional accuracy and long seal life. Cylinder rod is ground and hard chrome plated for scratch proof operation. World class seal kit is used for leak proof operation.

Hydraulic

Electric motor pupms, valves, hydraulic hoses, pipelines & fittings are used to reputed make for better reliablity of the machine.

Glycerine filled Pressure Gauge

Glycerine filled stainless steel pressure gauge is provided to watch the blending pressure. Additionally the required pressure may also be set using the knob.

Specification